In the spring of 2013, Accurate Perforating received a call from a project architect at CallisonRTKL, Stephen Funk. He was looking for a specific, custom perforated metal component to cover 3.2 linear miles of balconies for a new 40-story premier residential high-rise in Houston, Texas. CallisonRTKL had an ambitious design that required a perforator just as ambitious. The new building was to incorporate perforated railing panels on the building in a way that it would appear as a woman’s dress flowing in the wind. The railing panels needed to be a specific size and have a unique perforation pattern to support the design intent. Prior to contacting Accurate Perforating, Stephen was told by another company that the perforated components he required were not only unavailable, they were not possible. The building’s design was in jeopardy unless he could find the right company. Fortunately for Stephen, he called Accurate Perforating at the right time. Accurate has decades of experience manufacturing custom perforated metal components, the equipment to handle a huge array of options, and the adventurous mindset to find new solutions.

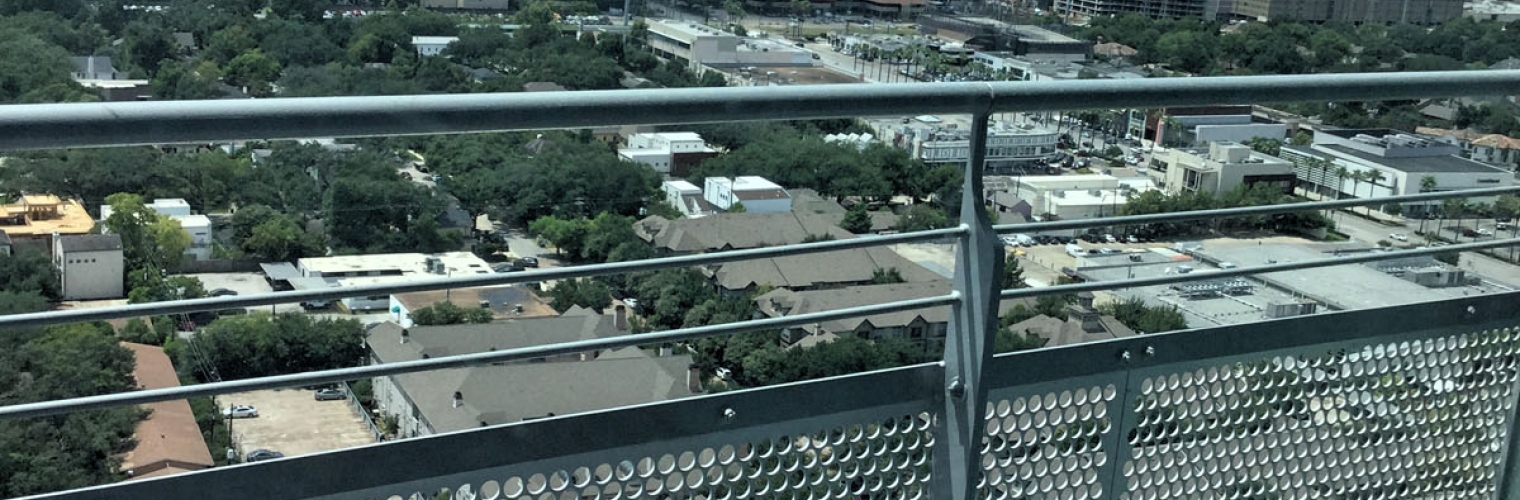

CallisonRTKL desired a custom-sized 36” wide perforated panel with a unique staggered perforation pattern. Another perforator that Stephen contacted gave him potentially project halting news. Apparently, only 4’ x 10’ perforated sheets were available, only steel could be used for the application, and the pattern they needed was not in existence. Not having the panels in the correct size would force the project to go over budget. Furthermore, the custom perforation pattern was essential to achieve the desired level of screening, safety, and most importantly, visibility that would deliver uninterrupted views of Houston. Eager for a solution, Stephen contacted Jeff Kaminsky, National Sales Manager at Accurate Perforating, based on a referral from a leading architectural product manufacturer. After speaking at length with Stephen to learn about the details and nuances of the project, Jeff explained that Accurate specializes in manufacturing custom-sized perforated sheets and since they have an in-house tooling department, building a custom perforating tool that matched their specifications was possible.

Jeff and Stephen were both also concerned about using perforated steel on the exterior of the building. Steel perforated panels, on an exterior application, are prone to rust. The building could end up looking like a reddish-brown weeping willow tree with rust stains dripping down the balconies and facade. Jeff sought the expertise of Accurate Perforating’s Architecture Project Manager, Bryan Pierik, to determine the feasibility of designing a custom panel that would meet all of CallisonRTKL’s requirements. After assessing in-house tool building and equipment capabilities, Bryan determined that Accurate was able to manufacture the railing panels in the desired perforation pattern in 3/16” anodized aluminum, eliminating rusting concerns. That additional material thickness gave CallisonRTKL the extra strength to handle the structural and wind load requirements. Accurate also designed the panels to have margins (unperforated section) with mounting holes throughout to provide numerous attachment points to further strengthen the railing system. As an unexpected benefit, the lighter aluminum panels required fewer personnel to install, resulting in substantial labor savings.

Accurate took additional steps to ensure the railing systems would enhance the beauty of the building throughout all of the 3.2 linear miles of balconies covering the 40-story building. They purchased the aluminum directly from the mill with sequential heat numbers in order to guarantee all aluminum panels would have the same appearance before and after the finishing process. Furthermore, Accurate provided a specialized Class I architectural anodized finish which offers superior quality and consistency specifically in high-value architectural applications.

According to Stephen Funk “Jeff was right on it from day one. He was very responsive. He took the time to educate me. He showed us the flexibility in their manufacturing; the kind of information that architects need to know; and helped us understand what was possible”. “With Accurate”, said Stephen Funk, “we were able to get the project back on track and within budget. Overall, Accurate gave us a better performing package.”

Project Participants:

- Building Owner: PMRG Realty Group

- Architect: CallisonRTKL:

- Vice President in Charge - Tom Brink

- Project Designer - John Munn

- Project Architect - Stephen Funk, Sr. Associate

- General Contractor: CF Jordan; David Weller

- Sub-Contractor: South Coast Manufacturing; Joe Ditta

- Railing System Design: CF Jordan; David Weller

- Perforated Railing Panels: Accurate Perforating