Perforated Metal vs. Expanded Metal—it is an age-old question that doesn't have a clear-cut answer. While we are clearly biased about which we think is best, we will take a brief dive into which product to choose: perforated metal or expanded metal.

What Is Perforated Metal?

Around here, we joke that "we put holes in metal". And, at its core. that's correct. Perforated metal refers to a type of sheet metal or coil that has been punched or stamped with a pattern of circles, squares, slots, or other shapes. These patterns can vary widely, from simple round holes to more decorative designs. Perforated metal is commonly used in various industries and applications due to its versatility and functional properties. It can be made from different materials such as steel, aluminum, stainless steel, copper, and others, depending on the specific requirements of the application. Perforated metal finds use in areas like architectural design, filtration systems, acoustic panels, ventilation, screening, and decorative purposes. Its perforations allow for airflow, light transmission, sound absorption, and visual appeal while maintaining structural integrity.

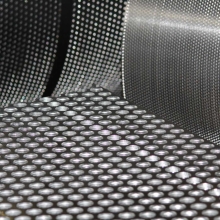

What is Expanded Metal?

Expanded metal is a type of sheet metal that has been slit and stretched to create a pattern of diamond-shaped openings. This stretching process results in a material that is stronger, lighter, and more rigid than the original sheet metal. Expanded metal can be made from various materials such as steel, aluminum, stainless steel, and others. One of expanded metal's key features is its versatility. It can be used in a wide range of applications, including fencing, grating, walkways, platforms, security screens, HVAC grilles, and decorative elements. The diamond-shaped openings allow for airflow, visibility, and drainage while providing structural support and security.

Deciding Between Perforated Metal Vs Expanded Metal

This decision is an ongoing predicament that many product designers, architects, and manufacturers are faced with today.

Far too often we hear that price solely determines many buyers’ selection process between the three. Price should be a factor when choosing one, but shouldn’t the selection of perforated, expanded, or wire also be about the application, the intended function, and the best product for the job? When comparing the capabilities of the three across a variety of areas, perforated metal exceeds expanded and wire in meeting many of those requirements. However, while perforated metal does offer a vast array of functionality, expanded metal or expanded mesh uses less scrap and may be more economical in some cases. A significant advantage of perforated metal is that it is typically stocked in a larger variety of hole patterns, materials, and gauges.

Also, this chart below comes from the handbook of the Industrial Perforators Association (IPA). It compares the functional capabilities of these three product types.

This information should help to make the most logical decision of material for your next product or project.

| |

Perforated Metal |

Expanded Metal |

Wire Cloth |

| Acoustical Capabilities: |

|

|

|

| Transparent to sound |

Yes |

Yes |

Yes |

| Absorbs specific sound frequencies |

Yes |

No |

No |

| Radiation Containment |

|

|

|

| EMI/RFI |

Yes |

No |

No |

| Microwaves |

Yes |

No |

No |

| Ventilation |

|

|

|

| Allows Airflow |

Yes |

Yes |

Yes |

| Filtration/Sorting |

|

|

|

| Control of flow rate |

Yes |

Yes |

Yes |

| Control of particle size contained |

Yes |

Yes |

Yes |

| Aesthetics |

|

|

|

| Control of design |

Yes |

Yes |

Yes |

| Control of lighting |

Yes |

No |

No |

| Control of ventilation |

Yes |

No |

No |

| Control of sound |

Yes |

No |

No |

| |

|

|

|

| Fabricating/Structural Considerations: |

|

|

|

| |

|

|

|

| "Open area" is part of a basic |

Yes |

No |

No |

| structural component and derives its |

|

|

|

| strength and physical properties |

|

|

|

| from it |

|

|

|

| |

|

|

|

| "Open area" is separate and |

Yes |

No |

No |

| attached to the structural component |

|

|

|

| and has its own strength and physical |

|

|

|

| properties |

|

|

|

|