Turning Challenges into Solutions: Collaboration, Innovation for Philadelphia University’s DEC Building

Innovative. Collaborative. These words aptly describe Philadelphia University’s ambitious new Design and Engineering Commerce (DEC) Building and the cross-disciplinary learning that will happen there. They also describe Accurate Perforating’s contribution to the project, and the reason Accurate was selected to fabricate the perforated metal shell that encircles the DEC.

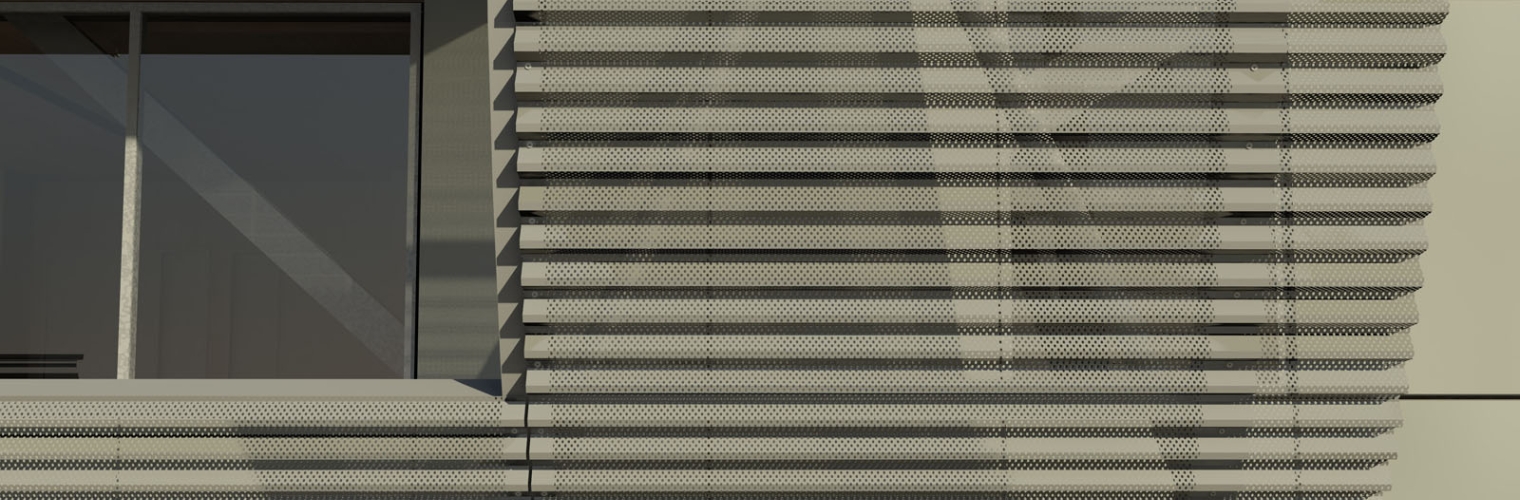

The PhilaU DEC is a 39,000-square-foot two-story rectangular structure with a plethora of windows and capable of morphing into alternate spacing configurations. The distinct exterior feature is the perforated metal shell arching effortlessly around the building with an aesthetically-pleasing sense of movement. The curved metal panels, which resemble watermill wheels and provide climate control, resulted in the building’s nomination for LEED Certification. The wheels also symbolize the progressive movement of the school’s approach to learning and the proud history of the city’s initiative in water sanitation. But the water wheels might not have easily spanned the building if Accurate had not detected a design problem.

Challenge 1: Initial Design Would Not Work

In consultation with a structural engineering firm, Accurate quoted the project with key improvements to the originally specified material thickness (from .050” to .080” aluminum) and corrugation profile (from 3 to 5 inches deep). This foresight won them the job and averted complications that could have compromised the structural integrity of the arches.

Challenge 2: Collaboration of Many

The entire project was an exercise in collaboration, with dialogue among partners vital. Making the DEC project a reality:

- Shepley Bulfinch (architectural firm that designed building)

- Accurate Perforating managed by Chris Berthold

- Structural engineering firm hired by Accurate

- M. Cohen and Sons (managed the installation)

The sheer number of parts and perforations also required precision at every step: 300 panels of 10 different lengths and configurations (some up to 20 feet in length); custom V-Beam corrugations, 5” deep; 3/8” x 9/16” perforations in the metal, with 40% open areas; and a class 1 clear anodizing finish.

Yet, there was one more challenge.

Challenge 3: Simplifying the Installation

The precision mounting holes pre-punched in the flat material had to align with the clearance holes in the structural steel after corrugating. If they didn’t match up, and weren’t clearly packaged with instructions, the on-site construction crew would have a problem on their hands. However, Accurate was able to deliver these panels to the site without any issues and therefore helped make the installation a success.

The Reward: Happy Customers and a Well-Designed and Beautiful Looking Building

Accurate Perforating was able to pull off the entire project without any re-makes and without any complaints from the field. Final assembly of the panels was completed without a hitch.

The DEC Building is the infrastructure for Philadelphia University’s ambitious idea—education to teach innovation and collaboration to solve complex problems. Accurate Perforating’s involvement in the ambitious project displayed innovation and collaboration as well, and at each step, problems were turned into solutions.

Here is an article that explains why green building is important to us.

Green Building - Sustainability Is Changing Our World