Stainless steel is a versatile material that has gained popularity across industries. The strength, corrosion resistance, aesthetic appeal, and functional versatility make it a primary metal for applications ranging from agricultural equipment to medical equipment to architectural projects. These properties also make it a popular choice for perforation. As a result, the demand for stainless steel perforated metal is rising. Are you intrigued to learn more? If yes, this guide delves into everything you need to know about stainless steel perforated metal, including its characteristics, grades, applications, benefits, and maintenance tips.

What is Stainless Steel Perforated Metal?

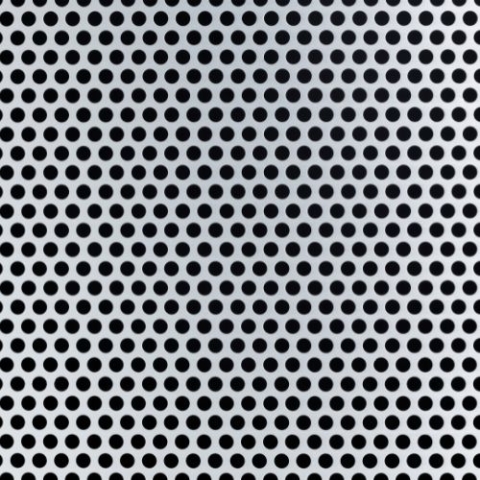

As the name suggests, stainless steel perforated metal is created by punching or stamping holes, slots, or patterns onto stainless steel sheets. These sheets are extensively used in industries for their performance, price, and aesthetics.

Types of Patterns

Stainless steel perforated metal may have perforations that vary in size, shape, and pattern. Some standard options include:

- Round holes are the most common type of perforations made on stainless steel sheets. There are two types of round hole perforations – straight and staggered. Straight perforations feature holes organized linearly in parallel rows, while staggered perforations may feature holes organized non-linearly. Depending on your application requirement, the sheet edges may be blank, unfinished, or finished. Round hole perforations offer balanced strength and open area up to 65%, which is one of the key reasons for their popularity. The perforations usually range from 0.03937″ - 0.393″ in diameter. Round hole perforations are common in applications that demand noise reduction, ventilation, and smooth airflow.

- Square holes: These perforations lend a contemporary look to your applications. Their linear arrangement creates larger open spaces than the same-sized round holes. Stainless steel perforated metal sheets can be stacked staggered or straight for effective results. The perforation sizes usually range from 0.078″ 0.7874″ in diameter. You can find square-hole stainless steel perforated metal sheets in industrial screens for sorting applications across mining and agriculture.

- Slotted holes: These perforated sheets are ideal for directional airflow or drainage applications. Stainless steel perforated sheets with slotted holes are distinguished by their elongated holes and square or round ends. They are organized in straight or staggered patterns. Slotted hole sheets find immense applications across industries where the passage of sound, light, and liquids is required. For instance, they can be found in machine guards, speaker grilles, and automotive components.

- Punch Plates: These sheets are CNC perforated and fabricated into a complete product. Stainless steel punch plates are extensively used in quarrying and recycling machines.

- Decorative Perforations: These sheets enhance aesthetics in architectural accents and can be customized to improve their appearance in an application.

- Hexagonal Stainless-Steel Sheets with Holes: These perforated metal sheets stand out due to their hexagonal pattern and staggered holes. In these sheets, the center of one hole aligns with the edge of the adjacent hole, forming an attractive pattern. Hexagonal stainless-steel sheets with holes possess a high strength-to-weight ratio, which makes them a popular choice for fences, facades, walkways, and steps.

Grades of Stainless Steel Perforated Metal

Several grades of stainless steel are used for creating perforated sheets, including:

-

303 Stainless Steel: This grade has high sulfur content and exhibits lower corrosion resista-

nce than the 304 grade. Applications include food processing and surgical equipment, shafts, etc.

- 304 Stainless Steel: This grade is known for its corrosion and heat resistance and is highly versatile, making it suitable for most applications. 304 stainless steel perforated sheets are widely used in chemical and brewing equipment, cryogenic vessels, and flashings.

- 304L Stainless Steel: This is an extra-low-carbon modification grade of 304 stainless steel, which is used in coal hopper linings and tanks used for storing tomato paste and liquid fertilizers.

- 316 Stainless Steel: This stainless steel grade offers superior corrosion resistance, making it ideal for marine or chemical environments.

- 316L: The perforated metal sheets made from this grade are stabilized for extreme corrosive conditions and applications in the 800 to 1600F temperature range.

- 410 Stainless Steel: This grade of stainless steel perforated metal sheet is used to create machine parts, pump shafts, and more.

- 430 Stainless Steel: This option is cost-effective for applications with less demanding environmental requirements.

Complete Guide to Perforated Stainless Steel Benefits

Stainless steel perforated metal sheets have gained immense popularity for the following reasons.

- Durability: Stainless steel is known for its immense strength and exhibits excellent resistance to wear corrosion, and high temperatures. These properties are not compromised by perforation. As a result, stainless steel is used in outdoor applications where it is exposed to environmental factors.

- Versatility: Stainless steel metal sheets are easy to work on and enable perforations. Thus, they can be easily perforated to meet various functional and aesthetic needs, from filtration systems to decorative facades.

- Sound Absorption: This is one of the prominent properties of stainless steel perforated sheets. They can easily absorb sound by dispersing sound waves, making them ideal for environments where distracting noises are a concern. These sheets' textured and porous surfaces help effectively absorb sound in many outdoor and indoor applications.

- Aesthetic Appeal: The modern, sleek appearance of stainless-steel perforated sheets enhances architectural designs, offering a blend of form and function.

- Ventilation: Stainless steel perforated metal sheets are used in construction applications for ventilation purposes. Many studies suggest that perforated panels can improve energy savings by at least 55%.

- Environmental Benefits: Stainless steel is 100% recyclable, making it eco-friendly.

Choosing the Right Perforated Metal Grade for Your Needs

Selecting the right perforated metal grade for your application can significantly impact performance, aesthetics, and budget. Consider the following key tips to make an informed choice.

- Understand Your Application Requirements: How will you use the perforated sheet? Will it be decorative, functional, or both? Consider factors such as load-bearing capacity, corrosion resistance, and environmental exposure.

- Determine the Right Perforation Pattern: Once you have identified the application requirement, ensure the pattern aligns with your project goals. Round holes offer large open spaces and are versatile, while square holes will give your application a contemporary look.

- Choose the Right Grade: Understanding the strengths and weaknesses of every grade will help you make an informed decision. For instance, if you are considering perforated metal sheets for marine environments, you can consider 316 stainless-steel grade. If you are considering them for lighter applications, then 304 stainless-steel grade will make a difference, and so on.

- Consider Open Area, which refers to the percentage of the sheet that is open due to perforations. A lower open area assures greater strength, while a higher open area improves airflow and helps reduce weight.

- Check the Gauge: Thinner gauges are more flexible and lightweight than thicker gauges. Thicker gauges can be considered for applications requiring higher strength.

- Address Environmental Factors: If you are considering perforated sheets for outdoor environments, ensure the metal has protective coatings, such as powder coating and finishing, to achieve resistance against environmental parameters.

Installation and Maintenance Tips

- Plan Ahead: Work with a perforator that can pre-drill mounting holes to make installation a breeze

- Use the Right Fasteners: Use corrosion-resistant fasteners, such as rivets and screws made from stainless steel, to ensure the appearance of the metal.

- Handle Sheets with Care: Although durable, these sheets may not withstand dragging through rough surfaces, so handle them with care and wear protective gloves during installation.

- Allow for Expansion: If your sheets are used outdoors, leave space for thermal expansion. Over time, thermal expansion can lead to warping and buckling.

- Consult Professionals for Complex Designs: Hire the services of professionals for intricate applications like noise control panels or architectural elements.

- Regular Cleaning: Clean the surface with mild soap and water to remove dirt and debris. Avoid abrasive cleaners that could scratch the metal.

- Inspect for Corrosion: Check regularly for signs of corrosion, especially in harsh environments, and address issues promptly.

- Protect the Surface: Use protective coatings or finishes for added durability in demanding applications.

- Inspect Fasteners and Fixtures: Inspect the fasteners and fixtures to ensure they are secure. Replace them if they show any signs of corrosion.

Stainless steel perforated metal is a versatile and reliable material with a wide range of benefits. However, to enjoy these advantages for years to come, it is essential to buy material from a trusted source.

Partner with Accurate Perforating for Superior Stainless-Steel Perforated Metal Solutions

Experience the unmatched quality and versatility of perforated stainless steel with Accurate Perforating. Whether you need durable, corrosion-resistant materials for architectural designs, functional HVAC solutions, or sustainable industrial applications, we've got you covered. With thousands of custom patterns created in materials ranging from 24 gauge to 1/4" thickness and widths up to 60", along with top-tier manufacturing expertise, we deliver premium stainless steel perforated sheets tailored to your specifications. Trust Accurate for innovative, long-lasting perforated metal solutions. Get ready to explore the endless possibilities with this remarkable material and transform your designs into reality with our experts.

Reference: https://www.iqsdirectory.com/articles/perforated-metal/perforated-stainless-steel.html