Good conservation starts with good design, and with the most recent addition to their green design cannon, The Ventura County Medical Center of Ventura, CA, the team at Accurate Perforating continues to follow this ethos to a tee. Accurate Perforating, a Chicago-based company, has forged the route for dynamic perforated metal designs for the past seventy years in projects all over North America, such as in New York’s JFK airport and at the New World Symphony Orchestral Academy. The 364 perforated metal panels which frame the custom designed medical center are composed of aluminum, that contains at a minimum 35% recycled content—and is 100% recyclable, to boot. But it’s not that Accurate Perforating’s metal sheets contain amounts of recycled metals, or that they can easily scrap unwanted projects to become the foundations for new ones—it’s how the perforation functions to help guide sound, light, heat and airflow to boost building performance on a variety of levels.

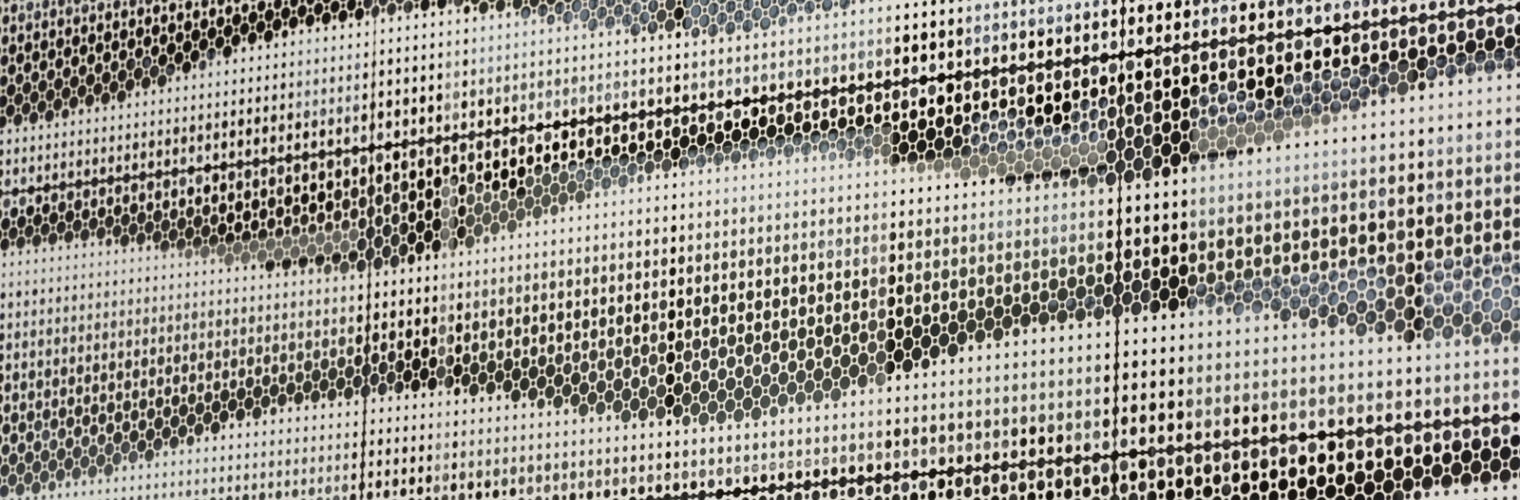

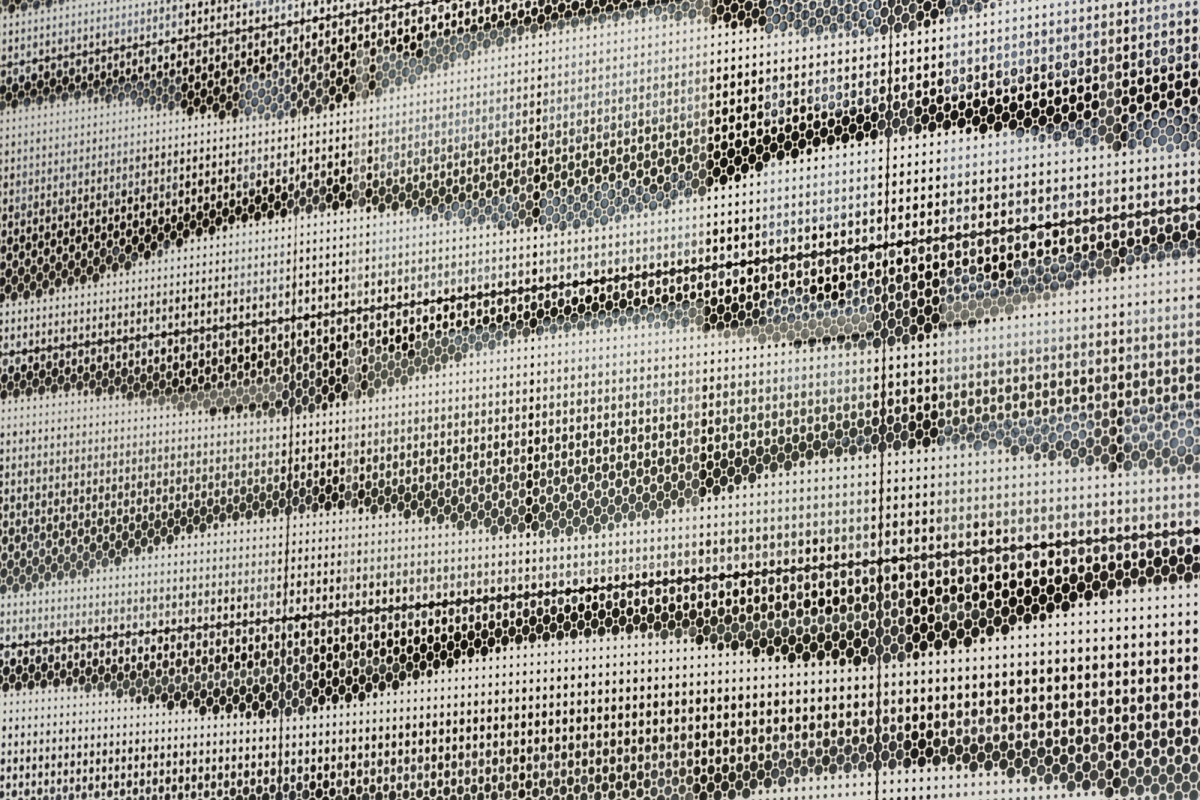

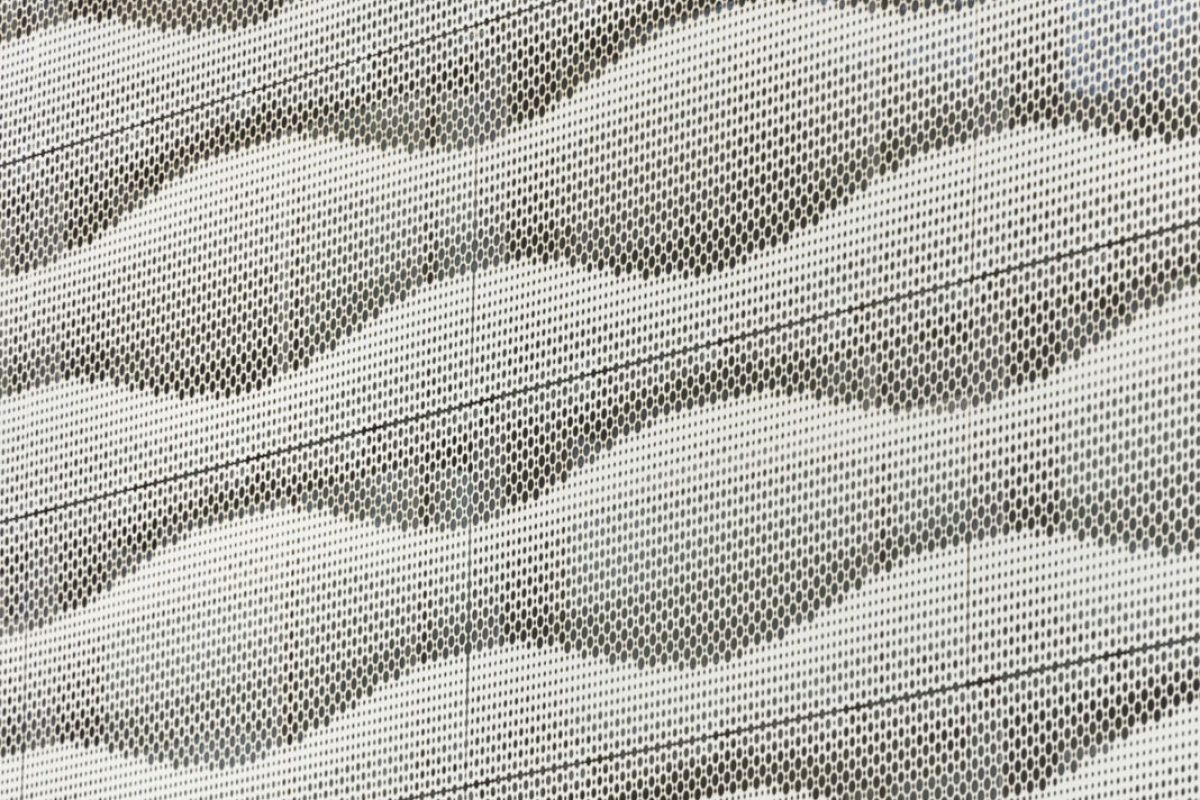

The East-facing medical center is in the target zone for massive amounts of glare and accumulated heat, especially in the early morning hours. “It would have made the whole area inhospitable,” says Damon Henrikson, Director of Marketing at Accurate Perforating. But the undulating design on the perforated panels both scatter glare, making it a pleasant speckle of ambient light, and cut the heat tremendously, without darkening the interior the way an opaque or solid shade might. At night, the light will peek through the wave pattern of perforations creating a beautiful “firefly” effect of the night sky being punctuated with pinpricks of warm light. “We chose this 2-D pattern that really looks 3-D,” says Senior Project Architect Paul Morgan. “The panels are versatile because the pattern was designed to self-contained within each panel, so the panels did not need to be installed in any particular order and the pattern flows seamlessly through all of them without anomalies or awkward terminations. They even turn 90 degrees without breaking the pattern,” Morgan explains. Beyond elevating the experience of guests and patients, providing a buffer to direct sunlight, while still maintaining excellent levels of natural daylight will help the Ventura Medical Center cut energy costs in the form of cooling and providing artificial lights.

With its ability to allow in natural light, yet provide a visual barrier, perforated metal sheets play a versatile cast of roles. Consider the Park Place parking garage in Missoula, Montana, a project using perforated metal in an earthy array of colors ranging from deep orangey-red to rich mahogany brown, which won it an Architectural Achievement Award for being visually captivating. “You can’t see the cars from the outside,” Henrikson explains. “Parking garages use them for screening so they’re not a blight on the neighborhood.” Beautifying a parking garage is a great application, but better yet, they may provide comfort for patients facing medical challenges. “The panels were designed to provide privacy to patient rooms,” says Morgan. “To prevent the public from seeing into the room from outside while allowing for enough natural light to enter the patient room,” says Morgan.

Privacy extends from visual, to sonic, as the panels assist a process called sound attenuation, which is the combined effect of sound scattering and absorption. “The configuration helps tune the room to give you the right amount of sound. It’s not an echo chamber; but it’s not a completely dead space.” This, too, like almost all elements of the perforated panels, is highly customizable. “Perforated metal can be adjusted to help you achieve whatever goals you have,” says Henrikson. You can adjust the size and shape of the holes, the patterns which appear on them, their configuration, and the spacing to fine-tune light, sound and ventilation,” he says. The materials of the panels can also vary depending on tastes and aesthetics, and include projects in bronze, weathered steel and copper. The holes themselves can make up abstract patterns, like on the medical center, or display a brand logo or composite picture when viewed from afar.

Accurate Perforating prizes durability in the future as well as the guest experience in the present, which is why it choses low-VOC, high durability finishes for all its projects. The panels on the Ventura County medical center are triple coated in Polyvinylidene Fluoride, a non-reactive polymer that is warranted to last two decades. Aluminum coated in PVDF is extremely resistant to corrosion, even in the face of salty coastal air, lowering maintenance and repair costs to practically nil, as the panels protect the structural materials behind them.

Lowering HVAC costs, cutting down on the need for artificial lighting during the day, and providing highly recyclable materials with supported longevity all help Ventura Medical Center become an excellent candidate for LEED and SMART certification (especially when APC reuses its own stores of scrap metal, neatly awaiting their next usage). By surpassing LEEDs “20% or more materials from recycled content” with flying colors, electing to use low-VOC finishes, and reducing the overall energy requirements of the building in a multitude of ways, Accurate Perforating’s portfolio, including the medical center, snap up LEED points with ease. The Ventura County Medical Center is expected to receive a LEED for Healthcare Silver level certification when the project is complete. The hospital design includes green roofs, a healing and viewing garden, skylights, exterior canopies and screens, and a pediatrics play area that will enhance the facility's healing environment. “The panels are one of my favorite things about this project because they came out so well” Morgan says. “I enjoy looking at them every time I walk in the building.”

By The Numbers:

- 70+ - Years Accurate Perforating has been manufacturing Perforated Metals

- 364 - Amount of panels at the Ventura County Medical Center

- 6,552 – Weight of the perforated panels

- 1,185,184 – Number of holes in all of the perforated panels

- 35% - The amount of recycled material APC’s panels contain

- 100% - The amount of material that can be recycled

- 3 - Coats of PVDF anti-corroding finish on each panel

Project Participants:

Architect: HOK

- Healthcare Sustainable Design Leader - Mara Baum

- Project Manager - Paul Morgan

General Contractor: Clark Construction Group

- Project Manager - Martin Soboda

Sub-Contractor: Sashco, Inc

- General Manager - Kathy Hoosier

Perforated Façade Panels: Accurate Perforating

- Sales Representative - Scott Ciley

SDC Architectural Solutions

- Project Manager - Chris Berthold