Perforated metal sheets are fabricated from stainless steel, aluminum, and copper materials. After the coil or sheet is fed through a perforating press, specific patterns like circles, slots, or other shapes are arranged uniformly across the sheet or coil. Despite the perforations creating openings, the strength and durability of the metal remain intact, making these sheets lighter and, in many cases, more visually appealing than solid metal products. An advantage of perforated sheets is that they allow airflow and light to pass while providing an effective guard from unsightly or otherwise dangerous items.

While perforated metal sheets are often chosen for their decorative and architectural qualities, their primary function in applications such as HVAC systems is to enhance ventilation and airflow. Acting like panels or dividers, perforated metal sheets can section off areas while maintaining the ambient temperature by allowing air to circulate freely through the perforations—something solid dividers cannot do.

Enhancing Ventilation in HVAC Systems

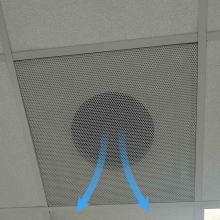

Perforated metal sheets are indispensable in HVAC system design and engineering. They enhance the appearance and protect system components, and they also play a crucial role in reducing noise. More importantly, perforated metal sheets are key to diffusing treated air from ducts, ensuring even distribution throughout a space.

As diffusers, perforated metal sheets help to distribute clean, treated air efficiently, contributing to a comfortable environment. This uniform dispersal is essential for temperature regulation, making the design and placement of perforated metal sheets a critical part of any high-functioning HVAC system.

Perforated metal sheets can control the flow of air by modifying the speed and pattern of the air stream as it passes through the openings. These openings' size, shape, and arrangement determine the airflow pattern, which can range from turbulent to laminar, ensuring proper ventilation. The perforations also regulate air transition from outdoor to indoor speeds, facilitating optimal airflow management.

Controlling Airflow Patterns

HVAC system designers, engineers, and installers use precise calculations to determine the appropriate open area of perforated metal sheets. This ensures that airflow is distributed correctly and the system performs at its peak, delivering consistent temperature control throughout the space.

One often overlooked benefit of perforated metal sheets in HVAC systems is noise reduction. HVAC systems can generate considerable noise from fans and motors, disturbing the environment. Perforated metal sheets act as silencers, muffling these sounds and creating a more pleasant atmosphere.

Beyond their functional advantages, perforated metal sheets are highly versatile in design. Available in various patterns and sizes, they fit into any décor, adding texture, color, and aesthetic appeal. The array of hole patterns allows designers to choose the suitable metal for both functional protection and design enhancement, making perforated metal a practical and ornamental choice.

Partitions

Privacy is often a concern in environments like restaurants, open meeting areas, and balconies. Solid partitions may block airflow and light, creating a stifling atmosphere. Large perforated metal sheets can be turned into partitions and offer the perfect solution, isolating spaces while allowing light and treated air to pass through.

A common misconception is that perforated metal sheets are solely decorative. While they do enhance the appearance of a room or building, their primary purpose is functional—especially in industries like HVAC and data centers. When manufacturers and engineers design perforated metal sheets for these industries, airflow, and ventilation are top priorities. The size and arrangement of holes with specific open areas and pattern types ensure proper airflow without creating excessive air pressure.