Whether for function or appearance, the right perforated pattern matters. What options are available, and how do you know what suits your application?

What Type of Hole is Best for You?

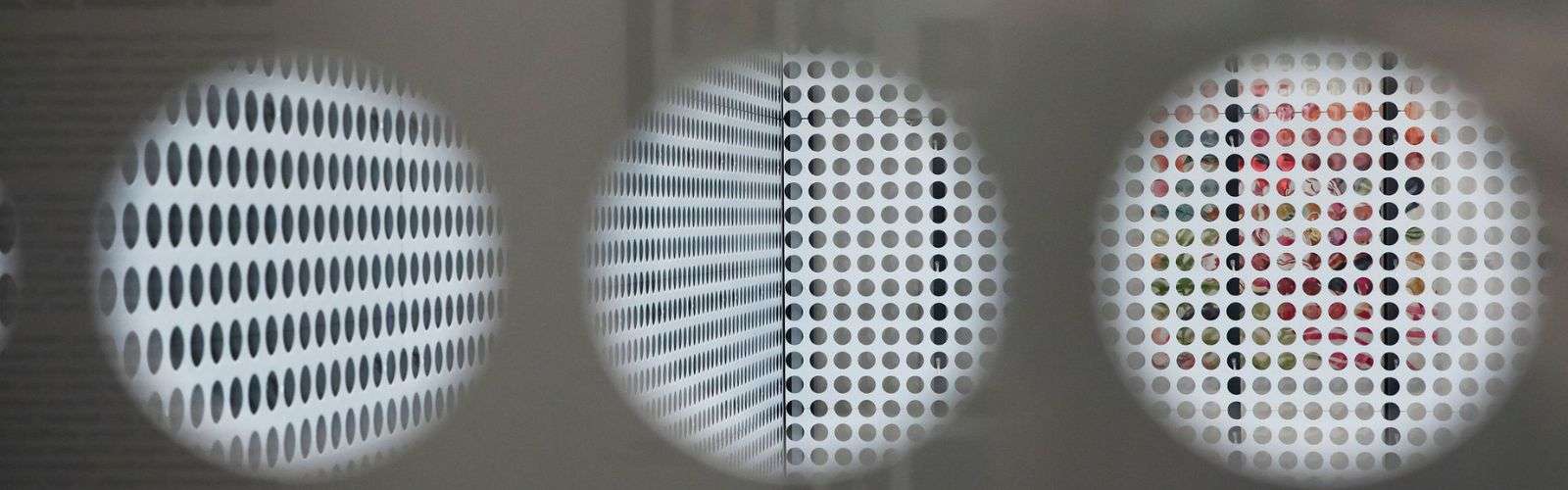

First, it helps to understand the types of holes commonly used in perforated metal patterns. They fall into four categories: round, square, slot, and ornamental or decorative.

Rounded holes are among the most common because they are relatively simple to do and can be the more cost-efficient option. In terms of applications, rounded holes are often one of the most universal and can be used in applications like air conditioning and heating. Round perforated panels are also commonly used as decorative additions to existing structures.

The next most common is square. The cost of producing square holes is higher than that of round ones because the corners put added strain on the corners of the punches. However, the benefits of square holes are impressive, including a more transparent view through the panel without sacrificing strength to resist impact.

Next, there are slot holes, essentially elongated holes with rounded or square ends. Cost-wise, they can be similar to square perforated holes. This option is most commonly used for industrial applications, including sorting materials like grains.

Lastly, there are patterns in the ornamental or decorative category. These patterns range from simple designs like hexagon, diamond, and cloverleaf shapes to very complex ones like Lincane, Saratoga, and Union Jack. They are frequently used in interior design for screening and decorative applications.

What are the Advantages of Certain Patterns?

You also have options when it comes to perforated design. The most common include staggered, straight, and ornamental.

Staggered means the holes are positioned to align diagonally or on an angle. The advantage of this can be a unique, attractive appearance. Staggered is typically limited to round holes.

Straight-line holes are precisely what you would think. The rows repeat in identical numbers of holes following the exact alignment. While decorative, this design is also suitable for functionality.

Some customers prefer an entirely customized look, or at least one that does not conform to traditional. Those include specific ornamental patterns like spirals or actual objects. These patterns are mainly for decorative purposes only.

Why Accurate Perforating?

Whatever your preference, Accurate Perforating has you covered. We understand the nuances of every option available. Because we live by a customer-centric business model, we work one-on-one with every customer to ensure we meet unique specifications. We can also powder coat in-house. Contact us today to learn more about how Accurate Perforating can help you achieve your perforated panels' perfect look and functionality.