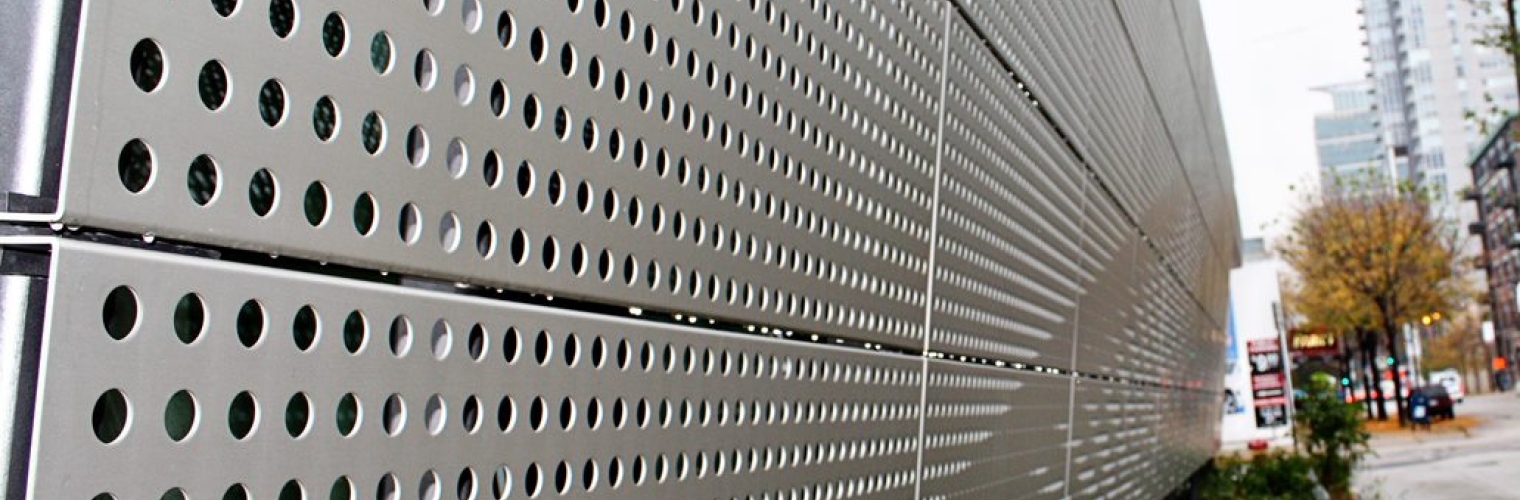

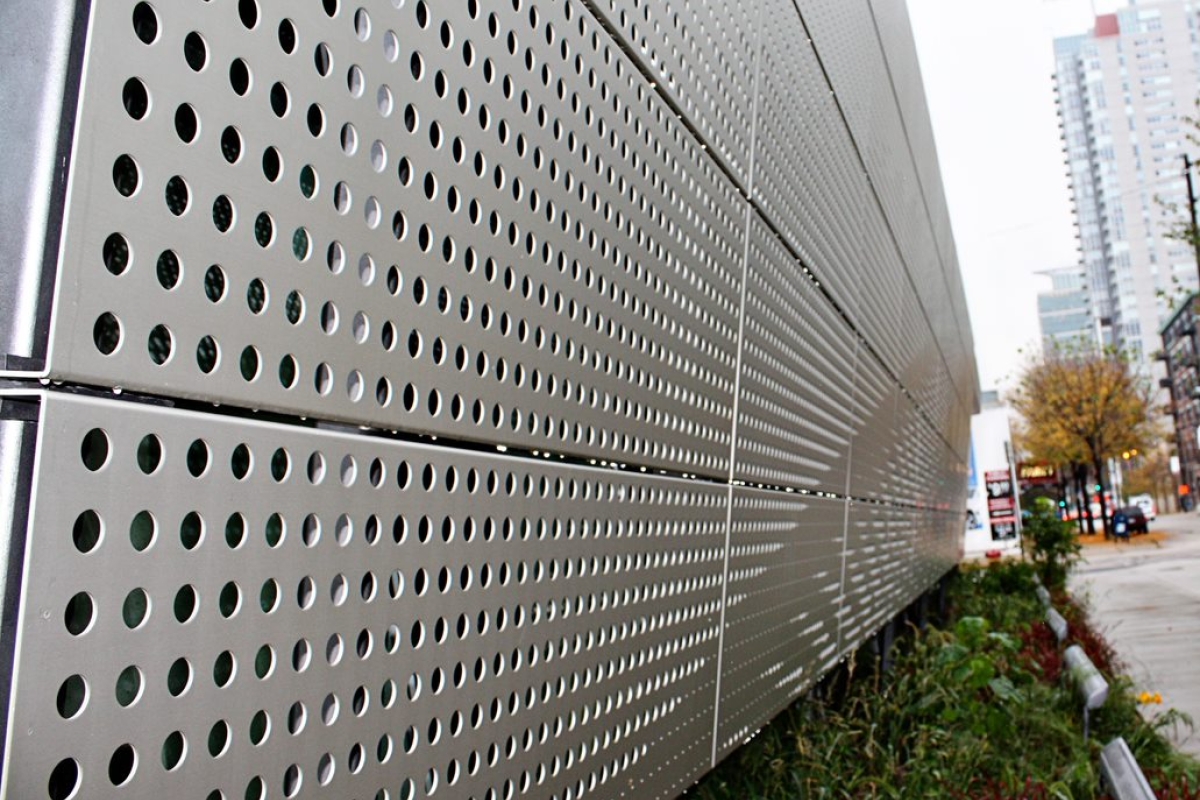

Accurate Perforating is known for creating beautiful, custom perforated screens. This building required 70 custom screens that not only looked great, but would also serve a practical function. The design of this 10,000-square-foot law office combines industrial materials with luxurious, refined finishes. From the outside, an aluminum split-roof lifts skywards and folds down over the south-facing glass wall as a perforated screen. Supported with steel beams, the permeable veil is part of the interplay between shared and private space.

With the main design elements of the Law Office being light and privacy, the architects of 4240 Architecture turned their focus to perforated metal and Accurate Perforating.

The finished product is a custom perforated facade that’s not only aesthetically pleasing, but also serves a practical function; providing privacy by reducing the ability to see in from the street, while still allowing natural light into the workplace. During the day, the perforated screen helps draw in a softer light by diminishing heat and glare from the sun. At night, the back lit screen is warm and seems almost lantern-like.

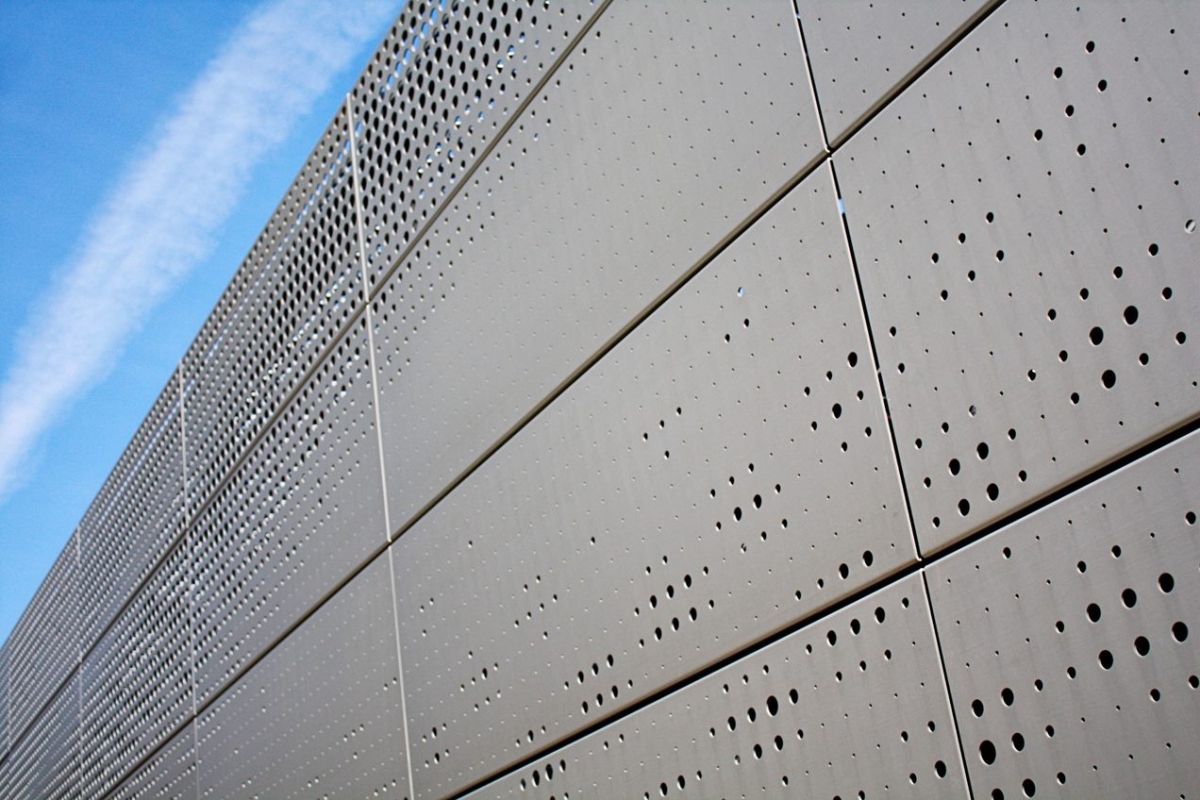

Although some may not see it, there is a graphic depicted within this pattern. The perforation pattern was designed to depict a carbon fiber roll waving in the wind. This element was important to the business owner; he wanted to incorporate his love of automobiles into the design.

In order to bring life to the architect’s design, Accurate utilized an array of experience and equipment. The final screen wall measures out to be approximately 1,200 sq. ft. and consists of 70 different panels each with a unique combination of hole diameters.

Perfectly framing the building required 20 different panel sizes. Each of the panels was perforated, notched, formed and clear anodized.

To aid in the installation process, our project management team went one step further by clearly marking each panel with a unique numbering system which told installers the location of each panel.

Due to manufacturing constraints and field conditions, the original design presented to Accurate required many revisions. Our project managers worked closely with the architect and engineers to help determine how the panels would attach to the support structures.

Although fabrication of the panels could not begin until the structural steel was up and final dimensions were obtained, Accurate was still able to deliver the finished panels to the job site ahead of schedule.

Project Participants:

Architect: 4240 Architecture

General Contractor: Norcon Inc.

Sub Contractor: Glass Solutions, Inc.

Photos: Modern Life Photography and Greg Murphey Studios